Case Overview

The partner in this collaboration is a large-scale dairy farm in western Santa Catarina, Brazil. The farm has 8.46 hectares of silage corn planting area (accounting for 59% of the dairy farm's land), with an average annual demand of about 700 tons of silage feed.

In 2024, the farm purchased a 9QS-4500T self-propelled silage harvester from Meidi to replace the inefficient operation mode of traditional manual labor and small equipment.

Customer Demand Characteristics for Products

The farm's core needs focus on tropical operational suitability, efficiency, and feed quality:

Operational efficiency requirements: The harvest window for silage corn on the farm is only 15 days, requiring at least 50 tons to be harvested per day, and matching the continuous operation rhythm of 6 transport trailers;

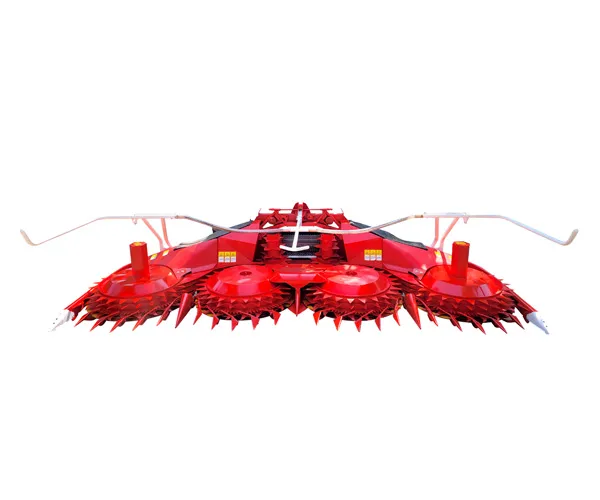

Tropical crop suitability: Brazilian silage corn varieties have thick stalks (about 8-10cm in diameter) and high moisture content (about 75%), requiring equipment with strong feeding capacity and precise grain crushing effect;

Environmental adaptability: The farm site is a hilly area with gentle slopes (slope ≤15°), and operations are frequent during the rainy season, requiring the equipment to have stable anti-slip properties and corrosion resistance.

Matching Product: Meidi 9QS-4500T Self-Propelled Forage Harvester

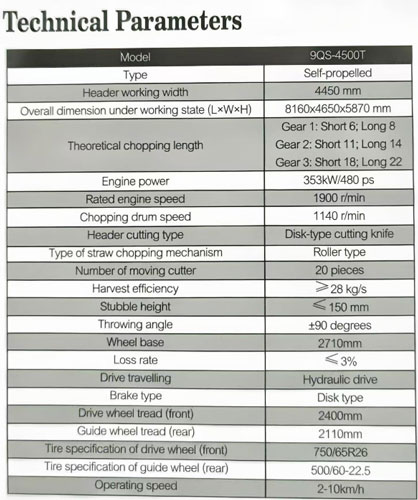

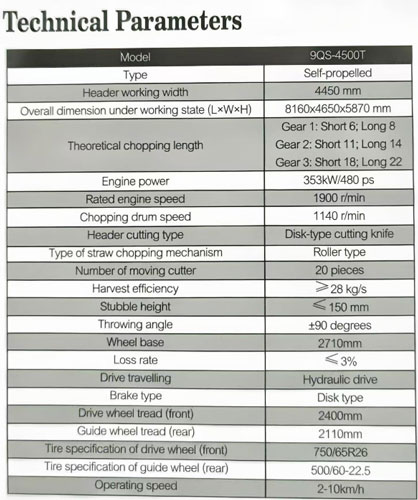

To meet customer needs, we offer the 9QS-4500T self-propelled silage harvester. Its core parameters and compatibility are as follows:

Operational efficiency: Equipped with a 480-horsepower engine and a 4.5-meter header, the actual operating efficiency reaches 100 tons/hour, and 600 tons of harvest can be completed per day, covering the farm's full-cycle needs;

Crop processing capabilities: Equipped with a drum-type chopping mechanism and a roller-type grain crusher, supporting multiple cutting lengths from 6-22mm, with a grain crushing rate of ≥97%;

Environmental adaptability: The drive wheels use large-size 750/65R26 tires, which improve the anti-skid coefficient by 30% and are suitable for hilly and gentle slope terrain; the body coating adopts a corrosion-resistant process to extend the rust prevention period.

Operation and maintenance: Equipped with an air-conditioned sealed cab (suitable for high-temperature operation up to 35℃), the machine's vulnerable parts adopt a standardized design and are compatible with local agricultural machinery parts markets.

Needs Matching and Pain Point Resolution

We address our clients' core pain points precisely through customized solutions:

Efficiency pain points addressed: The Meidi 9QS-4500T boasts an operating efficiency of 100 tons per hour, reducing the farm's harvest cycle from 15 days to 7 days, decreasing the working time during the harvest window by 53%, and preventing nutrient loss caused by over-ripening of crops.

Adaptation for tropical operations: For high-moisture crops, the speed difference of the grain crusher is optimized to ensure synchronous crushing of stalks and grains, resulting in feed uniformity of 92% (significantly higher than the customer's previous level of 80%);

Training services: Our technical team provides training, including equipment operation and blade adjustment, reducing subsequent maintenance costs by approximately 40%.